Well thought-out cooling

The importance of efficient cooling procedures must not be underestimated. Sophisticated solutions in this production step can affect the overall yield of the process immensely.

The most common way to chill meat products is to move the goods to cold storage rooms – although those are very ineffective! Due to the mere air chilling, it takes a long time to reach the product's required core temperature. This does not only result in long process times, but also affect the product-safety: The long period in a critical temperature range for microbiological growth (between 6° - 10° C) causes risks of product-contamination by microorganisms.

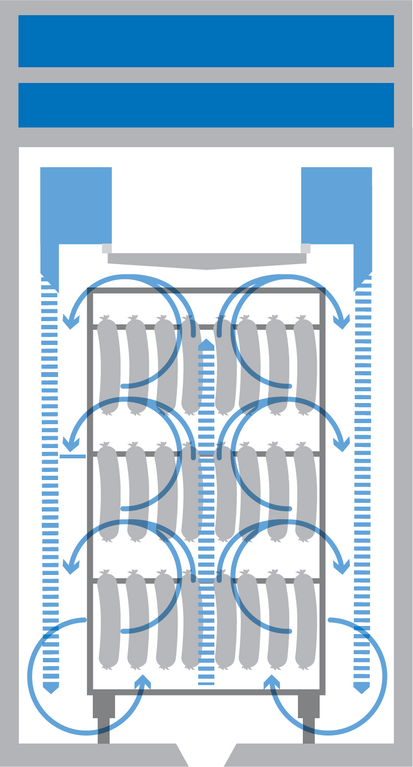

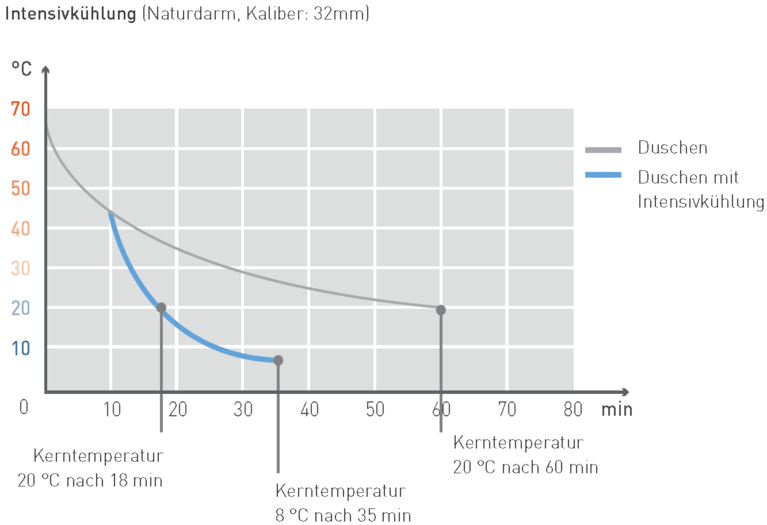

By using intensive cooling plants by FESSMANN, you can avoid all of these problems. Due to the alternating working principle of the evaporators, the intensive cooling systems are not only energy saving, but also reduce cooling times about up to 75 %!

As shown in the drawing, the exposure to critical temperatures can be shortened significantly. In the considered example (natural casing, calibre 32 mm) this process lasts not even 25 min – a true gain for hygiene and shelf life! The decrease of space requirements due to the elimination of big cold storage rooms is another positive side effect of the plants.

To avoid a weight loss of the products, intensive cooling plants by FESSMANN work with a particularly high level of humidity – increasing your yield additionally and speeding up the amortization of the machines!