360° Flavour!

Baked products are always a special challenge for manufacturers. Mainly, this is due to the high quality standards demanded by the customers: They expect an extra crispy crust and a perfectly tender core, without any irregularities in the colouring of course.

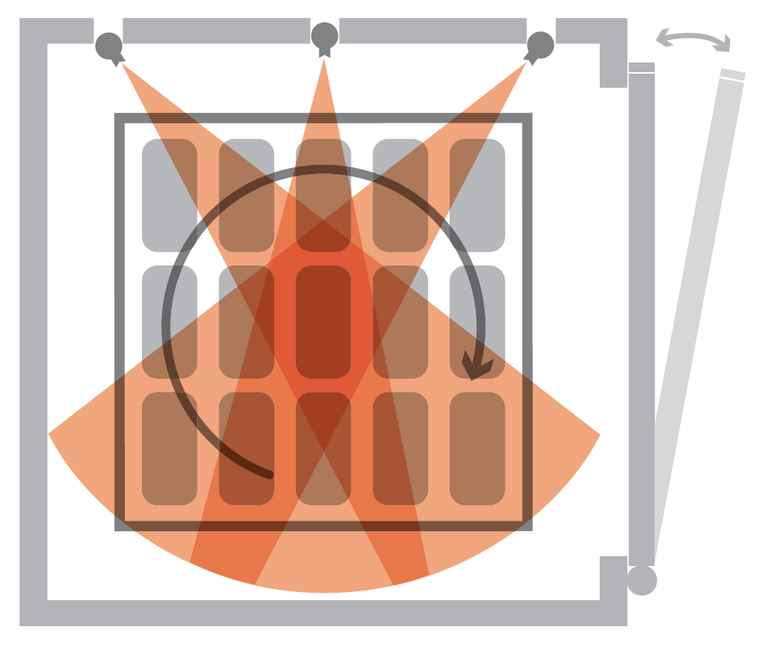

To fulfil these requirements, not only the temperature, but also the process time and a uniform airflow all over the products are decisive. A deviation of only one of those parameters can easily result in dried up products, an insufficient crust formation or differences in the colouring.