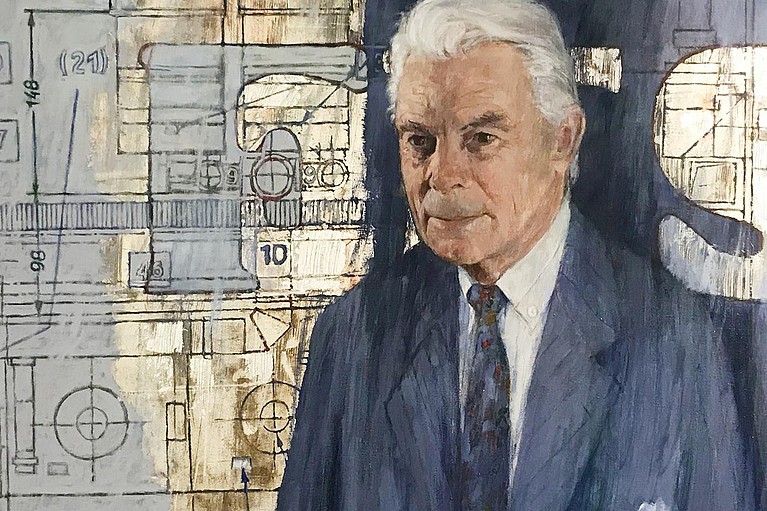

We practice tradition.

We practice the claims of founder Wilhelm FESSMANN.

A lot has changed at our Winnenden site since we were founded in 1924. We are now the proud market leaders in refining sausage, meat and fish. Our core competence is the production of smoking systems. Our solutions are used in small crafts operations as well as in big industrial companies.