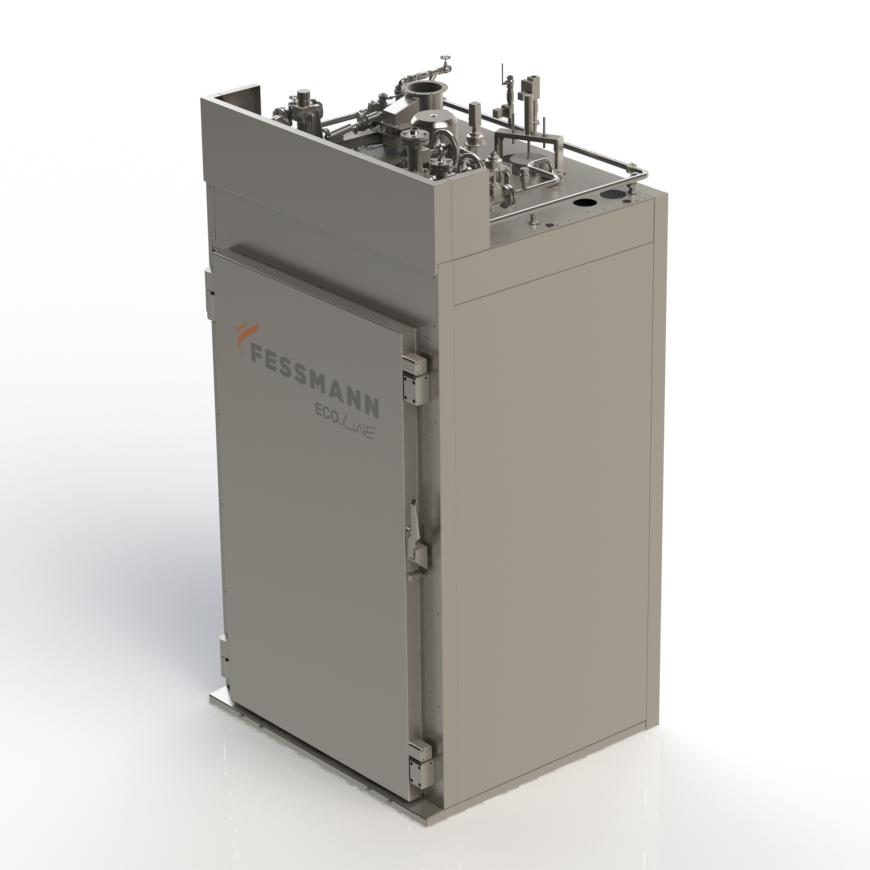

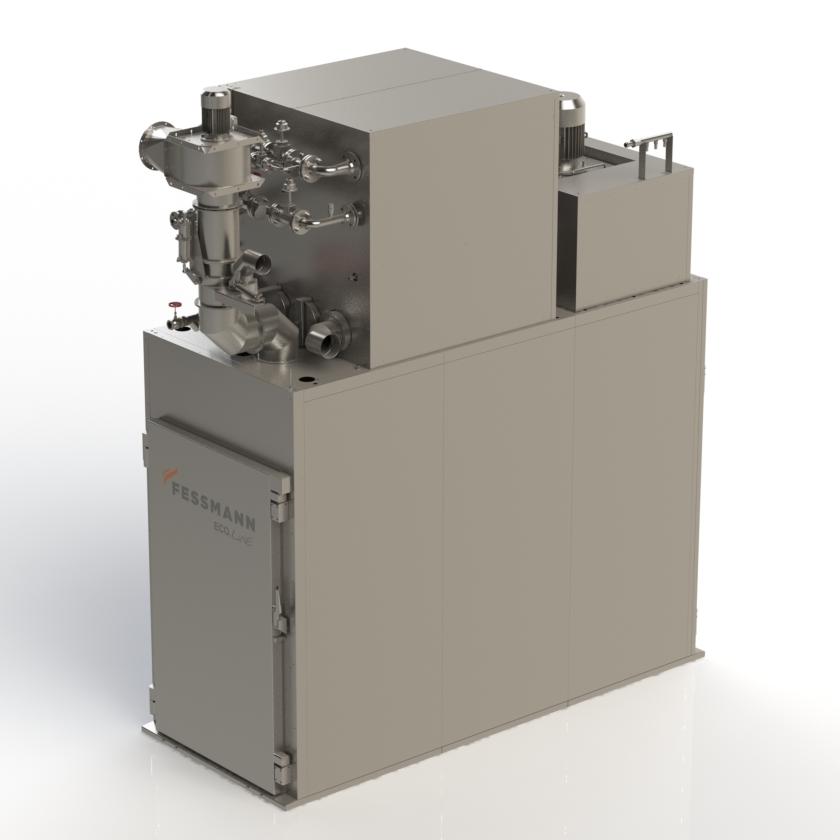

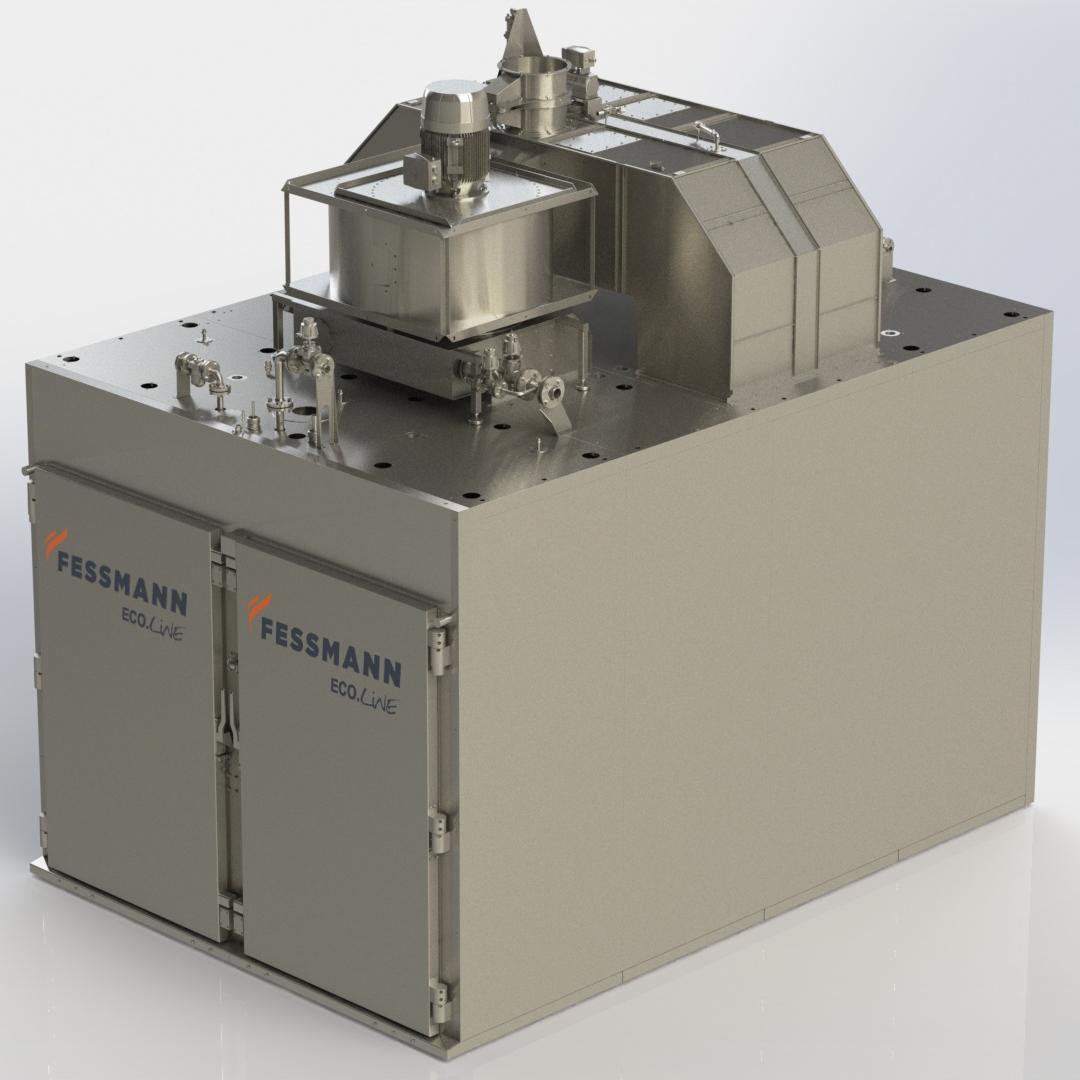

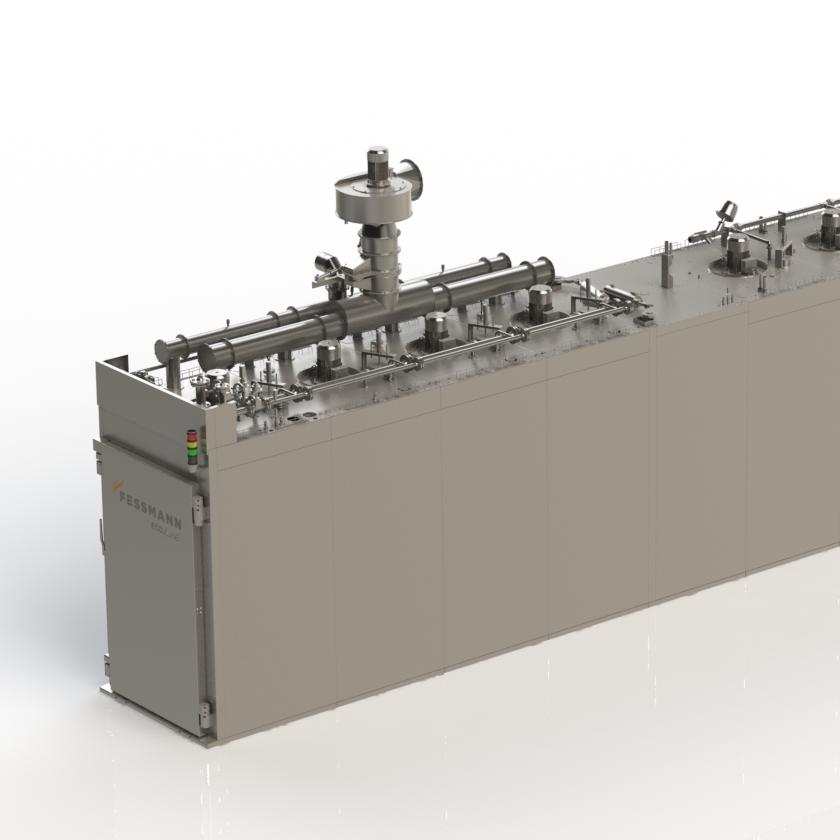

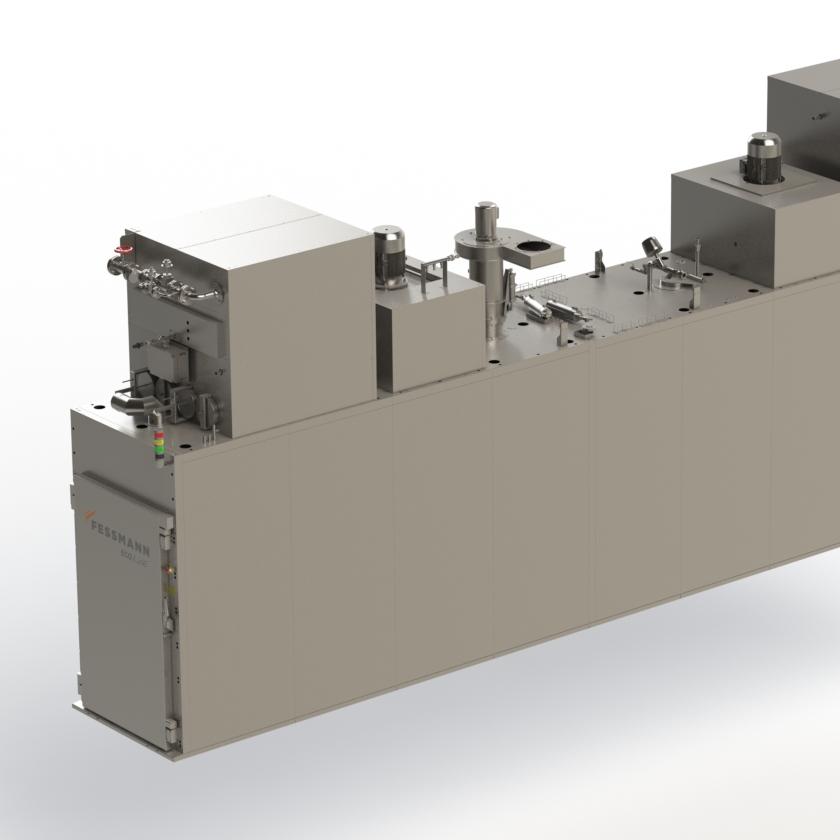

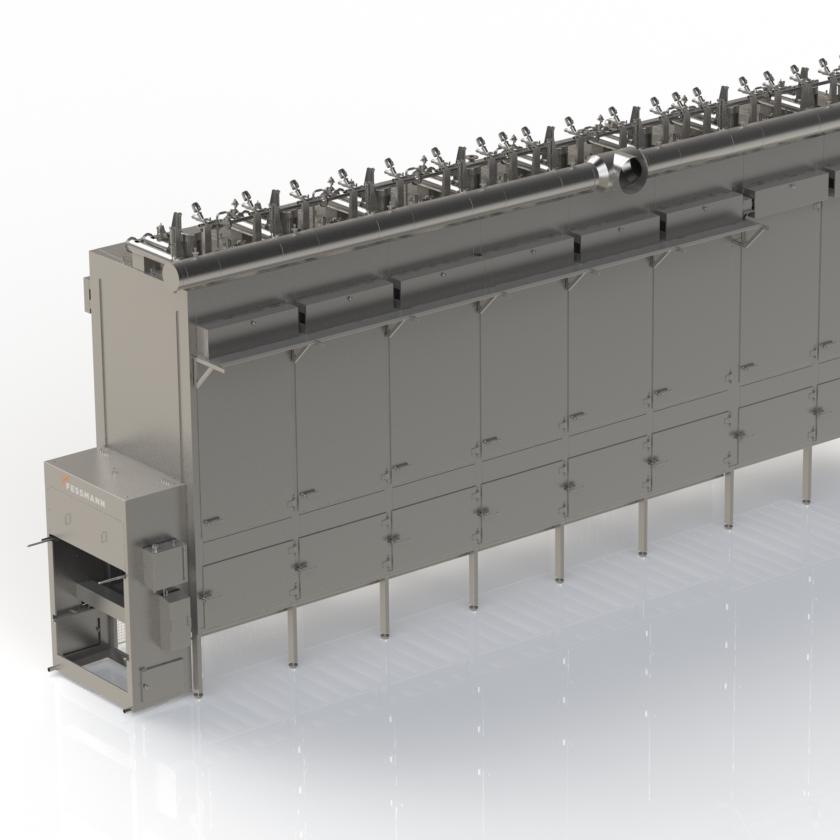

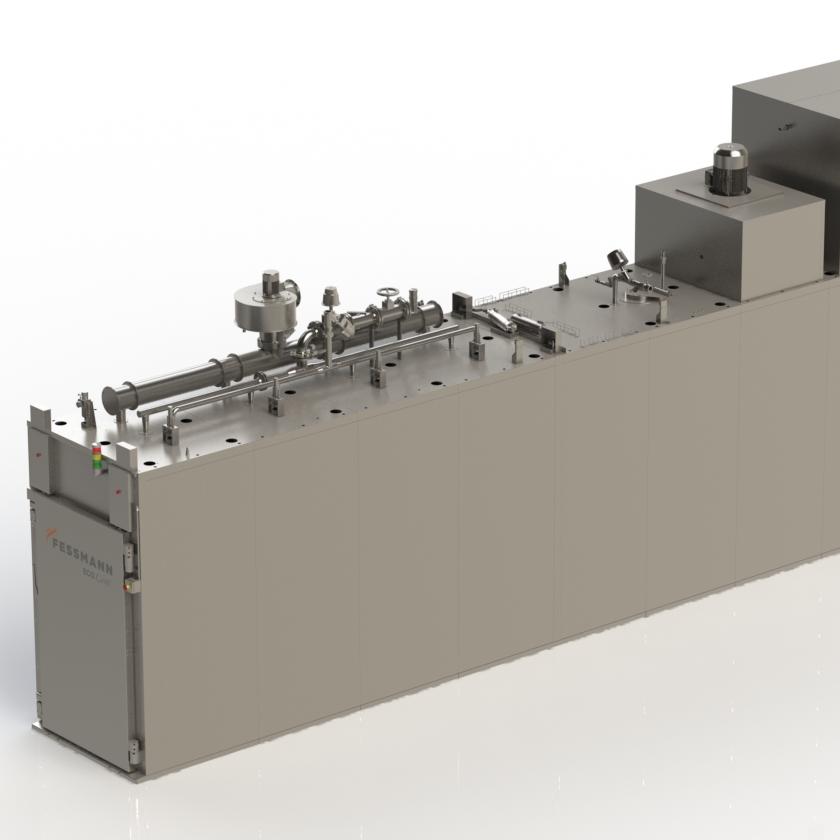

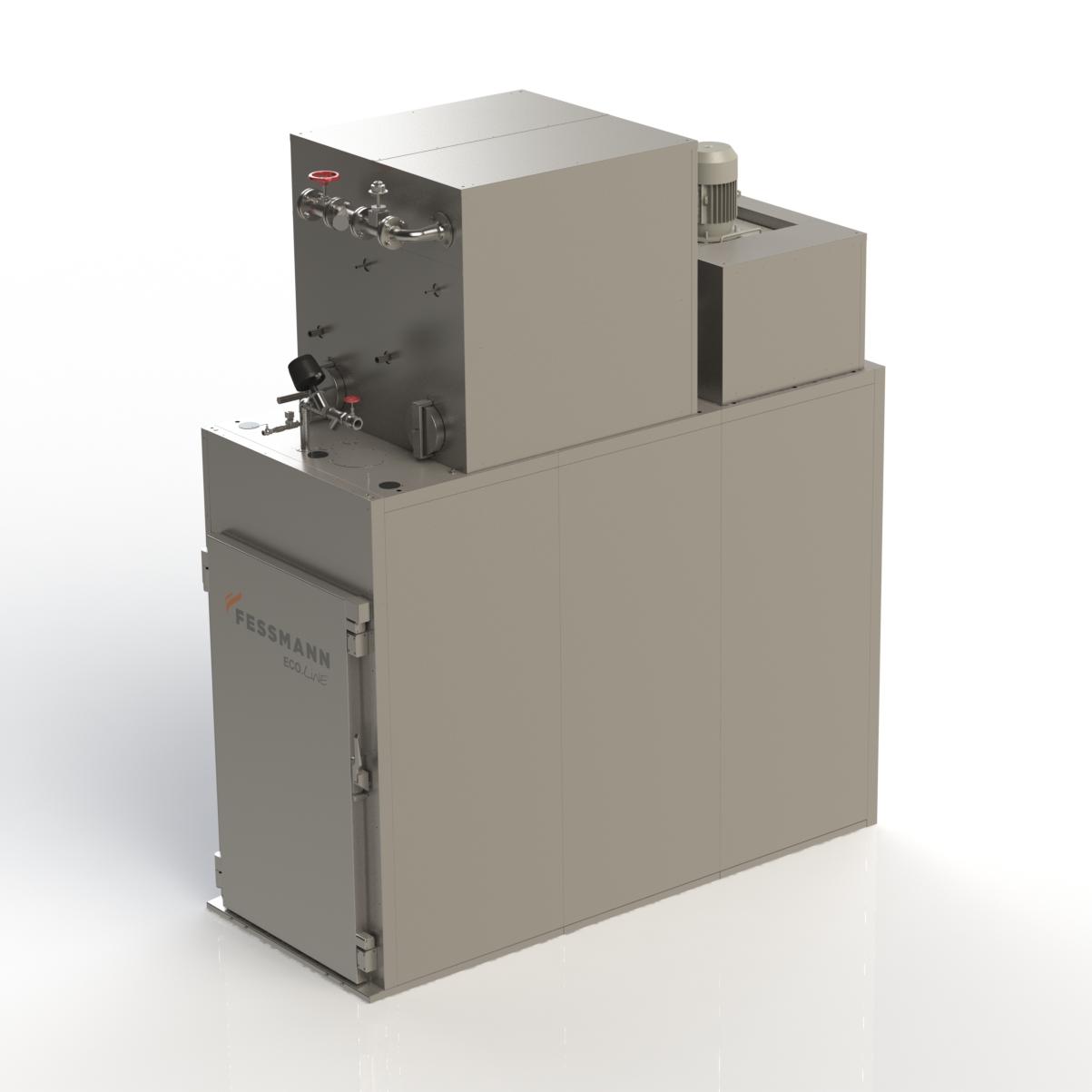

FESSMANN systems offer more

We refine food

For more than 90 years, we have been producing systems for processing and refining meat, sausage and fish. We do this in our family-owned company with a strong pioneering spirit, inexhaustible innovation power and unconditional customer orientation.

Our solutions offer less weight loss, short process times and best economic efficiency. Our customers most of all value the continually reproducible form and quality, as well as the uniform flavour.